The proposal is to use a low pressure tube to transport streamlined pods at subsonic speeds on air bearings between L.A and SF. The idea is that this would be a faster and lower cost passenger carrying alternative to an existing proposal for a high speed rail system between the two cities. With a broad brush of optimism, 300 odd miles can be covered in 30 minutes or less according to the report. And Elon Musk has marketed it pretty darn well.

Whether the idea is an original one I don't know since evacuated tube transport in capsules have been proposed before in the 90's (see image on right from one 1997 patent by Daryl Oster) and some even before that (see Atmospheric Railway). There's a lot of existing material on this topic however let's take a look at some of the aspects of the new study here.

Whether the idea is an original one I don't know since evacuated tube transport in capsules have been proposed before in the 90's (see image on right from one 1997 patent by Daryl Oster) and some even before that (see Atmospheric Railway). There's a lot of existing material on this topic however let's take a look at some of the aspects of the new study here.In the order of importance, I think that the tube construction will be prime since it has to withstand the pressure differential between atmosphere and negative pressure in the tube. I'm sure some ideas can be borrowed from systems such as large water pipes and tunnels. However, transporting passengers in this fashion will require extra factors of safety to make it idiot proof. Whether the imagineers behind Hyperloop will take a second look at welded steel for the tubes is to be seen.

Secondly, the study does not mention that passengers are expected to wear pressurized suits. Traveling in a low pressure tube will be like flying above 150,000 feet altitude. The cabin pressure has to be set to the right altitude to prevent passenger sickness and other physical harm. If compressors are expected to deliver the cabin pressure from bleed air, they have to be absolutely fail safe since it is a life system now, not just an air sucking device in front of the pod.

Related to this point, I don't know when was the last time an axial compressor flew at 150,000 ft. The maximum height an air breathing jet engine has flown is 85,135 feet which has been set by none other than the SR-71. Interestingly, the axial compressor spools in that engine would have been just windmilling at those cruise speeds as most of the thrust in the aircraft was delivered from the ramjet effect. To the same point, a jet engine operates in open air. The compressor in the Hyperloop is asked to operate in an evacuated tube. Can it work? I'll get back to the compression aspect later.

Thirdly, I'm reminded that an SR-71 executing a 6g turn at Mach 3 had a turn radius of 11 miles. Even though the speeds are much lesser in Hyperloop, centrifugal forces can be of concern. To transport 7.4 million people every year at over 700mph, optimum turn radii for the tube has to be evaluated along the route so as to keep g forces within acceptable levels. Some research indicates that the I-5 highway runs on topology that has small radii and varying terrain, flat in some places, steep in others. We can assume with reasonable confidence that the pylons and tube itself will be asked to do similar things.

Assuming the route is narrowed down, ride comfort evaluation has to done for a realistic group of people - average children, women and men. I'm sure there are rigorous industry standards that prescribe acceptable vibration and g forces in high speed railways and whether all the stipulations in these standards can be met is one big risk item.

Onto packaging. The study calls attention to keeping the capsule/tube area ratio as high as possible to avoid unfavorable aerodynamics, as the maximum speed possible in a pod within a low pressure tube is limited by something called Kantrowitz limit beyond which airflow is apparently choked and drag in front of the vehicle increases. I admit I haven't heard of this limit before but after a cursory glance at the physics, these limits seem to apply largely to supersonic speeds. Its desirable to shed further light on the time at levels spent in subsonic and supersonic modes to understand how these aerodynamic trade-offs factor into a representative transport situation.

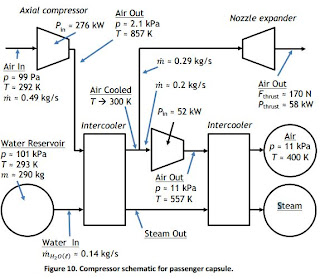

Onto packaging. The study calls attention to keeping the capsule/tube area ratio as high as possible to avoid unfavorable aerodynamics, as the maximum speed possible in a pod within a low pressure tube is limited by something called Kantrowitz limit beyond which airflow is apparently choked and drag in front of the vehicle increases. I admit I haven't heard of this limit before but after a cursory glance at the physics, these limits seem to apply largely to supersonic speeds. Its desirable to shed further light on the time at levels spent in subsonic and supersonic modes to understand how these aerodynamic trade-offs factor into a representative transport situation. Axial compressors are not known for high pressure rise within a stage. Some preliminary calculations I did suggest that to compress air of molecular weight 28.7 with desired weight flowrate of 30 lb/min from 100 Pa, 292K suction condition to 2100 Pa at discharge requires nearly 16 stages (mean blade velocity assumed to be 720 fps, pressure co-efficient = 0.29).

Axial compressors are not known for high pressure rise within a stage. Some preliminary calculations I did suggest that to compress air of molecular weight 28.7 with desired weight flowrate of 30 lb/min from 100 Pa, 292K suction condition to 2100 Pa at discharge requires nearly 16 stages (mean blade velocity assumed to be 720 fps, pressure co-efficient = 0.29).Assuming I'm right...

With the roughly 4.5 foot by 6 foot frontal dimensions of the proposed pod, I wonder how an onboard 16 stage compressor with intercoolers, valves, instrumentation and associated pipework can be squeezed into it and still expect to maintain aerodynamic shape. Of course this is just for the supplementary propulsion, as there is another compressor outlined in the study that supplies pressurized air to the air bearings and the cabin. If existing technology is used, the real estate for interstage coolers itself could be substantial.

Finally, there are key hardware items that require more refinement - the pumps needed to bring down the pressure of the tube to 90 thousandths of an atmosphere, the performance aspects of air bearings and linear accelerators to lift and move the pod, the performance of solar energy to power the pod in lieu of regional and seasonal differences in solar input. Finally, weather proofing those arrays...

I think that the biggest risk involved in Hyperloop is the proposal to use new technologies that have no previous run history. Hence, the validation/testing in terms of time and cost must not be underestimated. Those are the hidden costs of this project and if we consider those dollars as well, I wonder how the Hyperloop will compare to more conventional ideas.

A more refined Beta study including pertinent engineering details of various systems is required and this is where substantially more collaboration is needed. Being an opensource project, I take it that many engineers and corporations with expertise in various systems proposed here would like to rise to the occasion to help out.

Visionary thinking starts out with crazy initial concepts. The inertia to an idea is high, its something to be dealt with. I can already say that you'd need good bit of political muscle to get this idea across head honchos in government. Other engineering considerations have been outlined on other websites. I liked this particular one from Richard Gray at the Telegraph.

No comments:

Post a Comment